How Tata Electronic Chips in with key tieups in Dholera Smart City

Tata Electronics’ Big Leap Into Semiconductors: Strategic Tie-Ups Powering the Dholera Fab Revolution

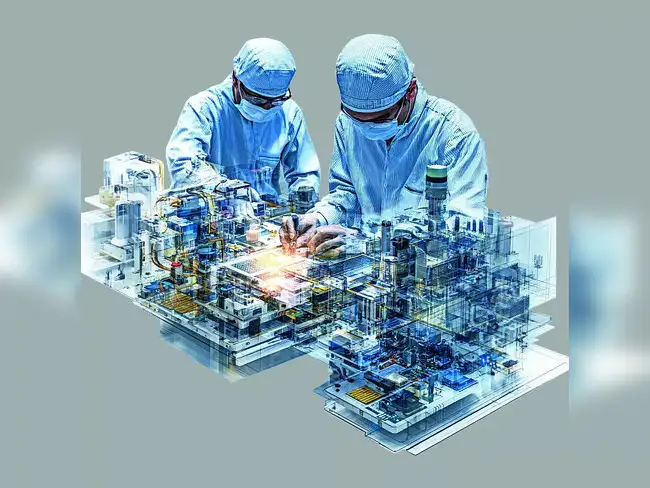

India’s semiconductor mission has entered a transformative era, and leading the charge is Tata Electronics, with one of the country’s most ambitious projects—a ₹91,000 crore semiconductor fabrication plant in Dholera Smart City, Gujarat. As the world searches for diversified, resilient chip supply chains, India is positioning itself as a strong alternative, and Tata’s strategic partnerships are accelerating this shift.

With a manufacturing capacity of up to 50,000 wafers per month, the Dholera fab is expected to roll out its first chip by mid-2027. This marks a milestone not only for Tata Group but also for India’s technological future. Alongside this, Tata Electronics is building a ₹27,000 crore greenfield ATMP (Assembly, Testing, Marking, Packaging) facility in Jagiroad, Assam, further strengthening India’s semiconductor ecosystem.

To make these mega facilities globally competitive, Tata Electronics has forged several high-impact collaborations with international leaders in chip manufacturing, electronics systems, semiconductor equipment, fabrication materials, and logistics. Let’s explore how these tie-ups are shaping India’s semiconductor future — and why Dholera SIR is at the center of this global shift.

1. The Tata–Intel Alliance (December 8, 2025): A Turning Point for India

In a landmark development, Intel and Tata Electronics entered a strategic partnership to explore manufacturing and packaging of Intel’s products at:

-

The upcoming Dholera semiconductor fab (Gujarat)

-

The Jagiroad ATMP facility (Assam)

This collaboration is monumental for multiple reasons:

-

Intel is one of the global leaders in advanced semiconductor technologies.

-

Manufacturing and packaging of Intel products in India signals global confidence in India’s semiconductor push.

-

The partnership can help accelerate technology transfer, skill development, and high-precision manufacturing capabilities.

For Dholera specifically, Intel’s involvement reinforces its position as India’s most advanced, globally aligned semiconductor zone. With India aiming to become a semiconductor export hub, this alliance could redefine the country’s participation in global value chains.

2. Merck Electronics Partnership (September 2, 2025): Strengthening Sub-Fab & Materials Ecosystem

Semiconductor fab success depends heavily on materials, chemicals, gases, and precision sub-fab infrastructure. Tata Electronics signed a significant collaboration with Merck Electronics, a world leader in semiconductor chemicals, specialty materials, and cleanroom technology.

The partnership focuses on:

-

Developing semiconductor materials and chemical capabilities

-

Strengthening sub-fab infrastructure like gas delivery, vacuum systems, and contamination control

-

Supporting advanced semiconductor process requirements

Dholera’s fab requires world-class materials and processing infrastructure, and this collaboration ensures that India's semiconductor ecosystem grows not just in manufacturing, but also in high-value upstream components.

3. Tata–Bosch Collaboration (July 17, 2025): Electronics Innovation Boost

Tata Electronics also entered a partnership with Bosch, one of the world’s leading engineering and electronics companies. Their collaboration spans several key areas within the electronics and semiconductor ecosystem.

Key goals include:

-

Co-developing next-gen electronic systems

-

Focusing on high-precision components

-

Supporting innovation in automotive electronics, smart manufacturing, and industrial IoT

Given that Dholera SIR is projected to attract EV, robotics, and advanced electronics manufacturers, Tata–Bosch synergy fits perfectly into the region’s long-term industrial roadmap. Bosch’s global experience can help build an integrated value chain for electronics manufactured in India.

4. Powering Defence & Electronics: Tata–Bharat Electronics (BEL) Partnership (June 6, 2025)

In June 2025, Tata Electronics signed an MoU with Bharat Electronics Limited (BEL) for:

-

Designing and developing advanced electronic systems

-

Manufacturing strategic, defence-grade electronics

-

Strengthening India’s self-reliance in secure and high-end technologies

For Dholera, this partnership is highly strategic. With space for secure, large-scale, defense-oriented manufacturing clusters, Dholera can become a major center for:

-

Radars

-

Sensors

-

Strategic communication systems

-

High-reliability semiconductor-based defence equipment

BEL’s collaboration injects credibility and long-term value into Tata’s semiconductor ambitions.

5. Tokyo Electron Partnership (September 2024): Core Equipment Backbone

No semiconductor fab can operate without advanced lithography, etching, and deposition equipment. And that’s where Tokyo Electron (TEL)—a global semiconductor equipment giant—plays a crucial role.

Tata Electronics’ agreement with Tokyo Electron covers:

-

Procurement of advanced semiconductor manufacturing equipment

-

Training Tata’s workforce on TEL’s high-precision machinery

-

Strengthening India’s semiconductor equipment knowledge base

This partnership ensures that the Dholera fab will be equipped with some of the world’s best tools — essential for producing high-quality semiconductor wafers.

6. Powerchip Semiconductor Collaboration (September 2024): Technical Expertise & Operational Support

In early discussions and progressing into strategic alignment, Powerchip Semiconductor Manufacturing Corporation (PSMC) of Taiwan is one of Tata’s closest technology partners for the Dholera fab.

Powerchip brings:

-

Decades of semiconductor fabrication expertise

-

Process technology know-how

-

Operational experience for running large-scale wafer fabs

For India, this collaboration is crucial. For Dholera, it is transformational. It places the region among the world’s emerging semiconductor manufacturing destinations.

Why Dholera Is the Heart of India’s Semiconductor Future

Dholera SIR offers unmatched advantages:

✔ Massive industrial land parcels suitable for fabs

Fabs require 200–500 acres of uninterrupted land—Dholera provides exactly that.

✔ 24×7 clean power with dual-source redundancy

Semiconductor plants need uninterrupted electricity. Dholera’s infrastructure ensures it.

✔ Abundant water supply

Fabs require millions of liters of ultra-pure water daily—Dholera has planned dedicated water pipelines and treatment plants.

✔ Seamless connectivity

-

Near the upcoming Dholera International Airport

-

Access to DMIC (Delhi-Mumbai Industrial Corridor)

-

Expressway links to Ahmedabad & key ports

✔ Pollution-free, low seismic risk zone

Perfect environment for high-precision manufacturing.

✔ Government-backed Semiconductor Zone

Financial incentives, approval single-window system, and strategic planning make it India’s No. 1 fab destination.

Conclusion: A New Semiconductor Era Begins in Dholera

With the ₹91,000 crore fab, the ₹27,000 crore ATMP facility, and global partnerships with Intel, Merck Electronics, Bosch, BEL, Tokyo Electron, and Powerchip, Tata Electronics is building nothing short of an integrated semiconductor powerhouse.

And at the center of all this innovation is Dholera SIR, India’s most promising and future-ready semiconductor and electronics hub.

For More Information Contact Us: - Dholera SIR

Add A Review

Your email address will not be published

Customer Reviews